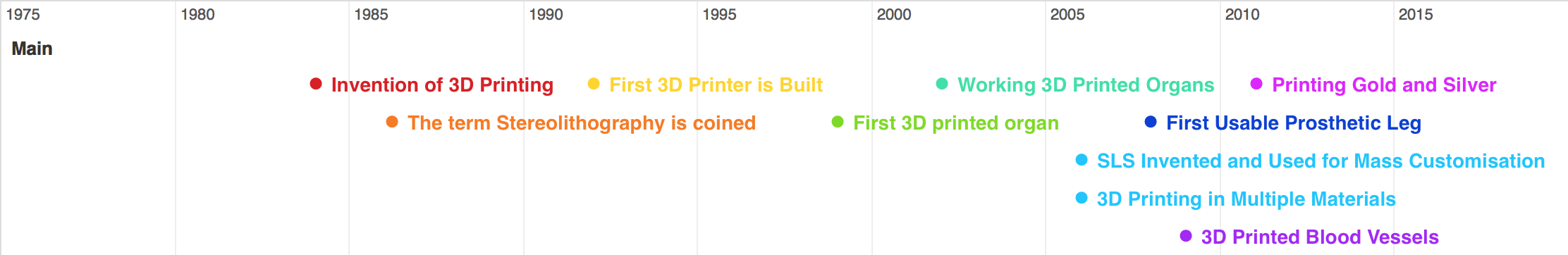

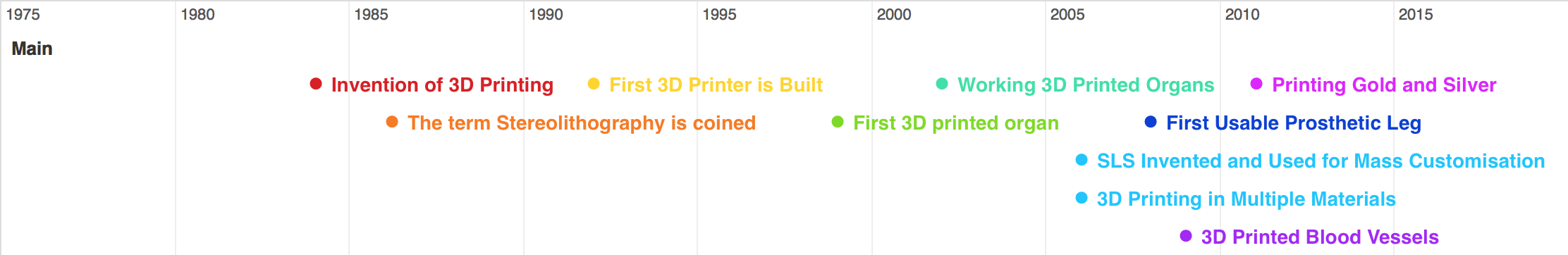

This is a timeline showing the progression of 3d printing through out time.

Learn how to apply the CAD skills you learned.

This is a timeline showing the progression of 3d printing through out time.

3D Printer’s have taken big steps, and there are bigger ones to come. Some of the big steps taken includes making prosthetic legs, making a blood vessel, making a robotic aircraft, making a car, printing jewelry in Silver and Gold, along with making a Prosthetic Jaw. There are bigger advancements to come, but you can see we’ve taken some big steps in the 3D Printing Business, and there are good things to come. Welcome to the future!

Now here are 5 fields which will benefit from the improvement of 3d printing. (Places you might want to work, if you enjoy 3d printing!

The automotive industry was one of the earliest adapters of 3-D printing to produce parts. But we could soon start seeing whole cars (or at least their bodies) printed. That's the business model for Urbee ("urban electric"), a startup auto company that wants to make the greenest car on earth. Stratsys, one of Credit Suisse's top stocks for investing in 3-D printing, just signed on as Urbee's sponsor for digital printing.

The automotive industry was one of the earliest adapters of 3-D printing to produce parts. But we could soon start seeing whole cars (or at least their bodies) printed. That's the business model for Urbee ("urban electric"), a startup auto company that wants to make the greenest car on earth. Stratsys, one of Credit Suisse's top stocks for investing in 3-D printing, just signed on as Urbee's sponsor for digital printing.

A company called EOIR Technologies developed a way to mass produce camera gun sights for M1 Abrams tanks and Bradley fighting vehicles using 3-D printing. Accroding to CSC, that cut the cost of manufacturing the gear by 60%. The Air Force is also in the initial stages of pumping out components of otherwise highly sensitive and expensive systems, like drones, in order to use them in training exercises.

Pick almost any simple soft-tissue organ — ears, fingers, even kidneys — and it's already being printed on a 3-D machine. So are 90% of all hearing aids, as well as an increasing number of dental equipment and hip and knee replacements, according to Credit Suisse.

Boeing now uses 3-D printers to create 300 different parts for its products.

For instance, according to CSC, Boeing's environmental control ducting (basically specialized tubes) used to have to be assembled from 20 small parts; now it's pumped out as a single piece.

This reduces inventory and maintenace costs, and also lowers fuel costs since the part is lighter. Some aerospace manufacturers are also deploying on-site printers for certain parts, reducing shipping costs.

Boeing now uses 3-D printers to create 300 different parts for its products.

For instance, according to CSC, Boeing's environmental control ducting (basically specialized tubes) used to have to be assembled from 20 small parts; now it's pumped out as a single piece.

This reduces inventory and maintenace costs, and also lowers fuel costs since the part is lighter. Some aerospace manufacturers are also deploying on-site printers for certain parts, reducing shipping costs.

If some storefront retailers are on the brink, 3-D printing may push them over the edge. Thanks to at-home printers — as well as places like UPS that have begun setting up printers at their stores — you may soon be able to print pretty much any relatively simple consumer good that would fit on your desktop.